The research analyses how 4.0 technologies can improve sustainability at logistics facilities, identifying opportunities for efficiency increase and environmental impact reduction. The study highlights several areas for improvement, considering economic, social and environmental implications.

With the increasing complexity of supply chains, the need to reduce delivery times and to address ever more demanding customers’ requirements, logistics managers are increasingly relying on a combination of warehouse solutions where manual activities coexist with automation, also supported by 4.0 technologies, in order to balance flexibility and efficiency. These developments also have environmental and social implications, and there is growing pressure from stakeholders to consider the impact of such 4.0 technologies on the sustainability of logistics facilities.

These implications are the focus of a study recently published in the International Journal of Production Research (IJPR) entitled “Reviewing and conceptualising the role of 4.0 technologies for sustainable warehousing”.

The study is the result of an international collaboration between the POLIMI School of Management of the Politecnico di Milano, with the participation of Prof. Sara Perotti and Eng. Luca Cannava, the University of Saarland in Germany, with the contribution of Prof. Eric H. Grosse, and the Bayes Business School in London, involving Prof. Jörg M. Ries.

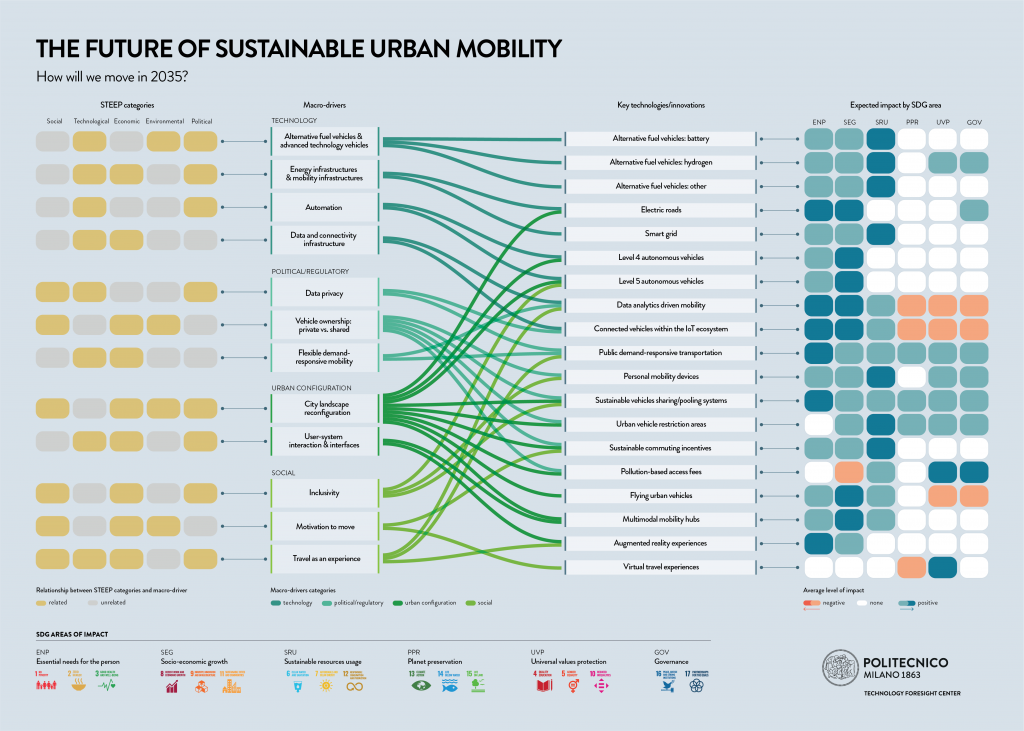

Starting from a careful analysis of the scientific literature, the study develops a conceptual model to assess the sustainability impact of 4.0 solutions applied at logistics facilities, evaluating the economic, environmental and social perspectives, as well as the impact in terms of the Sustainable Development Goals (SDGs), by examining the application of 4.0 technologies in the different warehouse processes (e.g. receiving, storage, picking, packaging and shipping).

This systematic approach has made it possible to identify areas of intervention to make the warehousing processes more sustainable (e.g. in terms of reducing both consumption and carbon footprint), and to improve the operators’ working conditions according to a human-centric approach.

In particular, the research shows how the benefits of 4.0 technologies can only be achieved through an efficient integration within warehouse processes, whose effectiveness is closely linked to the processes involved. With regard to the spillovers associated with the adoption of 4.0 technologies, there are still major challenges related to the environmental and social impacts of such innovations.

Finally, the study identifies four main areas of development and opportunities for the future:

- “Opportunities from a processual perspective”: related to the nature of warehouse processes, with a focus on picking activities;

- “Opportunities from a technological perspective”:technological opportunities, including those related to the application of artificial intelligence solutions;

- “Opportunities from a measurement perspective”:opportunities related to measurement/quantification both in terms of environmental KPIs and metrics related to the activities carried out by the operator, with a focus on the data collection and processing phases;

- “Opportunities from a sustainability perspective”: opportunities related to sustainability, particularly in contexts where automation and operators coexist.

To read the complete article: Reviewing and conceptualising the role of 4.0 technologies for sustainable warehousing