What is the circular economy and how can it become part of our daily lives? We asked Simone Franzò, Director of the International Master in Environmental Sustainability & Circular Economy at MIP.

When we talk about a circular economy, what are we referring to?

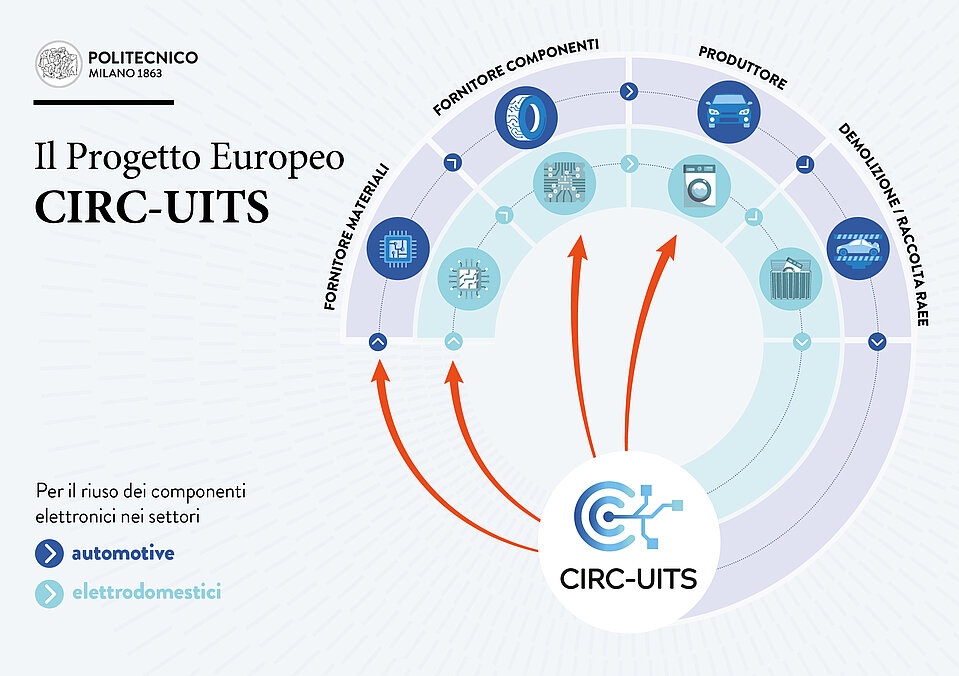

A circular economy is an “emerging” economic model that contrasts with the traditional “linear” model (summarised with the terms take – make – dispose) and aims to maximise the efficient use of resources. Reuse and maintenance of products, extension of their life cycle, recovery and recycling of materials are just a few of the practices on which a circular economy is based. It is a model that brings benefits not only to the environment, but that also generates new business opportunities. This is why we study the managerial implications that this model can have in companies that intend to apply it.

McKinsey actually predicts that, in Europe alone, the move to a circular economy could generate €1.8 trillion in profits by 2030. Are companies ready to seize these opportunities?

First of all, I would like to make a premise: the topic of the circular economy is part of a broader context, which is that of sustainability. This is subdivided into three different perspectives, namely environmental, economic and social, which must be considered jointly to enable so-called sustainable development.

That said, from my point of view, companies are increasingly sensitive and aware of the impact that their activities have, not only for themselves, but also for the “context” within which companies operate. However, translating this growing awareness into concrete initiatives aimed at pursuing the goals of sustainability and the circular economy is a very important challenge in many respects, primarily at a cultural level. In fact, it is a question of moving from a “purely economic” orientation, aimed at maximising the value that the company creates for shareholders, to a broader perspective, which provides for the creation of value for all stakeholders as well as, of course, for the shareholders.

A qualitative leap from the cultural point of view, however, is not enough; a change is also needed on the managerial side. Adopting the principles of the circular economy, in fact, requires the company to make significant changes in terms of strategy – that is, to shift from traditional business models, linked to a linear economy, to new, circular models. This obviously has important repercussions from an operational point of view as well. It is no longer enough to think in terms of the company, but we need to move to a broader perspective, that of the supply chain, involving for example suppliers and customers. This is a significant challenge from a managerial point of view.

This is an interesting perspective, but how does it translate into career opportunities – both present and future? Why should a young person entering the job market choose this sector?

There are many careers that can be undertaken in this area. The potential consequences associated with the spread of the circular economy – as shown by the numbers cited above – are enormous. However, it is appropriate to reflect on the new skills required of companies, primarily from a managerial point of view, in order to enable the transition to the circular economy, which opens up important windows of opportunity for young people (and others) looking for a job. Consider, for example, the need for a company to redesign its range of products and services, as well as the business model through which they are offered. In fact, designing new products, services, or business models based on the principles of the circular economy requires specific skills, which are different from those traditionally relied upon to design linear-economy services and business models.

In addition to the impact on innovation processes, all the other business functions must be imbued with the principles of the circular economy: think, for example, of logistics – which in some cases play a crucial role in the implementation of circular business models – and purchasing to marketing, to make customers aware of the characteristics of the “circularity” of the products and services offered by a company.

MIP offers five different Masters dedicated to the topic of sustainability and one is dedicated to the circular economy. Why is this?

As I said, the issue of sustainability is quite broad and encompasses three perspectives: environmental, economic and social. The theme of the circular economy definitely plays a central role in the broad focus of sustainability, to the extent that implementing circular economy business models can enable the achievement of sustainability goals.

May I say that, in this context, our Business School is an ideal place to study and analyse these phenomena. In the first place, because of the coherence between this topic and the purpose of our School, which aspires to make a positive impact on society by inspiring and collaborating with the innovators of today and tomorrow. What we can also offer our students is a particular focus on the study and analysis of strategic issues related to the management of a business. This is an important element for those who want to guide companies towards circular business models, given that change must also be addressed from a strategic-managerial point of view. Moreover, we take a “data-driven” approach to problem solving, in line with the engineering imprint that characterises our Business school and, more generally, the Politecnico di Milano.

A final element that distinguishes our range of courses is our strong collaboration with companies. For the International Master in Environmental Sustainability & Circular Economy we have already involved about 15 companies as sponsors. This provides a number of opportunities for our students, from company testimonials during the training course – which give the theoretical sessions an experiential configuration – to the possibilities of internships or carrying out the project work at the end of the Master at companies, in order to be able to apply what you have learned during the Master in the field.